Serving industries such as commercial, retail, industrial, residential, electronics, and entertainment, AC power cords are used with applications like electrical power tools, lighting, household appliances, musical instruments, shop equipment, and numerous personal uses. AC power cord manufacturers and AC power cable suppliers offer all kinds of AC power cord options to accommodate this broad range of applications. Read More…

Our customers find we have the highest standards when it comes to quality, and delivery. Quail Electronics is a worldwide power cord supplier, offering power cords and various other products.

All of our power cords are tested and stand up to rigorous demands of everyday application. We serve a global market including the United Kingdom, Ireland, Germany, Switzerland, Austria and of course the United States.

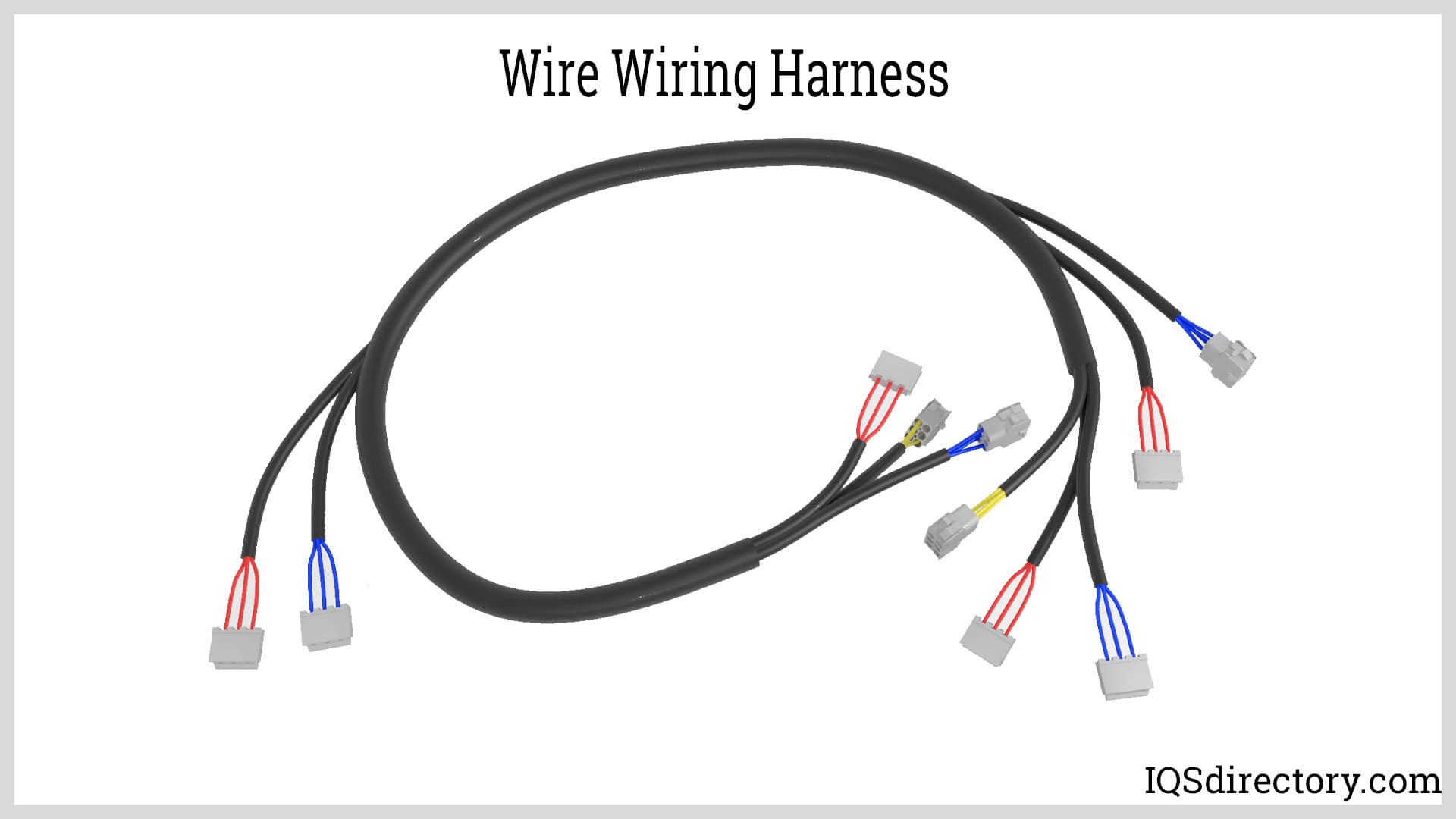

US Cordset Manufacturing provides power-supply products to various categories of customers from domestic to industrial. Our line of products include wiring harnesses, Coiled cords, extension cords, processed wires, high voltage twist lock cords, and more. Whether your requested electrical configuration is simple or intricate, our expert staff is ready to help.

Our plug adapters are guaranteed to bring you a lifetime of value. Our staff is committed to bringing you only the most reliable products that are available. We will find solutions for your cord needs regardless of how difficult the job may be.

At Americord, we dedicate ourselves to delivering high-quality power cords and custom wiring solutions that meet the demands of diverse industries. We design and manufacture durable cords that are tailored for performance, safety, and reliability, serving applications ranging from consumer electronics and industrial machinery to specialized equipment requiring precise electrical connectivity.

At Cord-Sets, we dedicate ourselves to delivering high-quality power cord solutions that meet the needs of industries across the globe. We specialize in designing and manufacturing power cords, cord sets, and related components that are engineered for durability, safety, and reliable performance.

More AC Power Cord Manufacturers

Comprehensive Guide to AC Power Cords

AC power cords are fundamental to modern electronics, delivering safe and reliable electrical connectivity between power sources and devices. Whether you are equipping a data center, medical facility, manufacturing plant, or simply need replacement power cables for home use, choosing the right AC power cord is essential for electrical safety, device performance, and compliance with industry standards. In this in-depth guide, we’ll cover AC power cord construction, types, standards, ratings, use cases, and expert tips for selecting the best cord for your needs. This resource is ideal for facility managers, procurement professionals, engineers, installers, and informed consumers.

What is an AC Power Cord?

An AC power cord, also known as a mains power cable or line cord, is a flexible, insulated cable assembly designed to transmit alternating current (AC) electricity from a wall socket or power distribution unit to electrical or electronic equipment. Unlike DC power cords, which carry direct current, AC power cords handle the alternating flow of current that is standard in most residential, commercial, and industrial power grids.

Key features of a typical AC power cord include:

- Conductive wires: Most often copper, chosen for its superior conductivity and mechanical flexibility.

- Insulation and jacketing: Protective layers such as PVC, rubber, or thermoplastic elastomer (TPE) that electrically isolate conductors and defend against abrasion, heat, and chemical exposure.

- Connectors: A male plug (for the wall outlet or power strip) and a female connector (for the device), both manufactured to specific regional or international standards for a secure, safe fit.

High-quality AC power cords are engineered for durability, electrical safety, and compatibility with a wide range of devices, including computers, monitors, printers, audio/visual equipment, industrial machinery, and medical devices. The right cord ensures not only power delivery, but also protection against electrical hazards, interference, and environmental stressors.

AC Power Cord Construction and Materials

The performance and reliability of an AC power cord depend on its construction and the materials used. Understanding these elements is crucial when evaluating power cord specifications for your application.

- Conducting Medium: The internal wires are usually made from stranded copper for optimal electrical conductivity and flexibility. Some specialty cords may use tinned copper or aluminum for specific resistance or cost requirements.

- Insulation: The primary insulation layer prevents short circuits and shields the conductor from contact. Common materials include PVC (polyvinyl chloride) for general use, rubber for flexibility, and TPE for enhanced oil and chemical resistance.

- Jacket: The outer sheath provides mechanical protection. Options such as SJT, SVT, SJTW, and others denote specific jacket materials and construction standards, indicating suitability for indoor, outdoor, or industrial environments.

- Connectors: Molded or assembled terminations ensure the cord fits securely into outlets and devices, reducing the risk of accidental disconnection, arcing, or wear. Connectors are available in a variety of shapes (straight, right-angle, locking), grades (hospital, industrial, commercial), and standards (NEMA, IEC, international).

Manufacturers offer a broad range of AC power cord specifications that include:

- Voltage rating (commonly 125V, 250V, 300V, or 600V for specialized applications)

- Current rating (such as 10A, 13A, 15A, 16A, 20A, and higher for industrial cords)

- Wire gauge (expressed in AWG or mm2), impacting current capacity and cord flexibility

- Cord length options (ranging from 1 foot to 100+ feet for extended reach)

- Jacket material (PVC, SJT, SJTW, SVT, rubber, TPE, and more for specialized environments)

- Plug and connector types (straight, angled, locking, hospital grade, shielded, weather-resistant, etc.)

For unique requirements—such as custom lengths, unusual connectors, or specialized ratings—consider a custom cable assembly designed for your application.

Types of AC Power Cords and Plug Standards

AC power cords are produced in a wide variety of types to support global plug/socket standards, device compatibility, and unique use cases. Selecting the proper type is critical for electrical safety, device protection, and ease of use.

NEMA Power Cords (North American Standard)

The NEMA (National Electrical Manufacturers Association) standard defines the majority of plugs and receptacles used throughout the United States, Canada, and parts of Central America. NEMA-rated cords are essential for compliance in residential, commercial, and industrial settings.

- NEMA 1-15 (Type A): Two flat parallel blades, ungrounded. Used for low-power devices such as lamps, chargers, and audio equipment.

- NEMA 5-15 (Type B): Two flat blades with a grounding pin. The most common household plug for computers, appliances, and office equipment.

- NEMA 5-20, 6-15, 6-20, and others: Provide higher voltage or current ratings for heavy-duty and commercial equipment. Locking NEMA plugs (L5-15, L5-20, etc.) are used for secure connections in demanding environments.

Are you unsure which NEMA configuration suits your device? Use our NEMA power cord compatibility charts to find the right match for your power requirements.

International Power Cord Standards

Global variations in plug shapes, prong arrangements, and electrical ratings mean that the choice of AC power cord must reflect your region or the destination market for exported products. Here are the most common international types:

- Type C (Europlug): Two round pins, used throughout Europe, South America, Asia, and Africa for low-current, non-grounded applications.

- Type E/F ("Schuko"): Two round pins with side grounding contacts. Predominant in Germany, Austria, the Netherlands, Scandinavia, and other parts of Europe.

- Type G: Three rectangular blades, including a ground. Standard in the United Kingdom, Ireland, Singapore, and the Middle East.

- Type I: Flat pins in a V-shape with an earth pin, found in Australia, New Zealand, China, and Argentina.

- Type D, J, K, L, M, N, and others: Used in specific regions; always verify local requirements before purchasing.

International power cords are also rated for regional voltage and frequency (e.g., 230V/50Hz in Europe, 240V/50Hz in Australia, 120V/60Hz in North America). Choosing the correct international AC power cord is crucial for travelers, OEMs, distributors, and global supply chains.

IEC Power Cords

IEC (International Electrotechnical Commission) power cords are standardized worldwide, especially for computers, servers, network hardware, and test equipment. The most common are:

- IEC C13 to C14(often called a "kettle lead")—Used for desktop PCs, monitors, and servers.

- IEC C5 (cloverleaf) and C7 (figure-8)—Used for laptop power adapters and small electronics.

- IEC C19/C20—Heavy-duty applications such as data centers and large servers.

Do you need help choosing between IEC and NEMA cords? Compare cord sets vs. power cords here.

Applications and Use Cases for AC Power Cords

AC power cords are indispensable across a vast array of industries and environments, supporting everything from consumer electronics to mission-critical industrial systems. Common applications include:

- Consumer Electronics: TVs, desktop computers, monitors, printers, audio equipment, gaming consoles, and home entertainment systems.

- Home Appliances: Refrigerators, microwaves, washing machines, air conditioners, vacuum cleaners, and kitchen gadgets.

- Industrial Equipment: CNC machines, power tools, welders, conveyors, HVAC systems, and industrial lighting.

- Medical Devices: Hospital beds, ventilators, infusion pumps, patient monitors, imaging devices (MRI, X-ray), and laboratory analyzers. Hospital-grade cords are required for many applications.

- Information Technology: Servers, racks, network switches, routers, UPS backup systems, and data center infrastructure.

- Office Equipment: Copiers, shredders, projectors, teleconferencing devices, and POS terminals.

- Specialized Uses: Outdoor-rated cords for landscaping, construction, and events; locking cords for secure industrial connections; shielded cords for EMI/RFI-sensitive environments.

Are you searching by device type or industry? Filter by voltage, connector, or application for a tailored AC power cord solution.

Key Factors to Consider When Choosing an AC Power Cord

The right AC power cord maximizes equipment reliability and user safety. Consider these essential buying criteria:

- Voltage and Current Rating: Select a cord rated for the maximum voltage and current your device will draw. Overloading can cause overheating and fire risk.

- Plug and Connector Type: Ensure compatibility with both the device and the outlet or PDU. Use country-specific or universal adapters as needed for international travel or export.

- Wire Gauge (AWG): Thicker wires (lower AWG) support higher currents and longer runs. Use manufacturer charts to choose the correct gauge for your application.

- Cord Length: Select a length that offers flexibility without excessive slack (which can cause tripping hazards or voltage drop).

- Jacket Material and Environmental Ratings: Choose oil-resistant, weatherproof, or chemical-resistant jackets for harsh environments. Look for outdoor, hospital-grade, or shielded cords as required.

- Safety Certifications: Only use cords certified by recognized agencies (UL, CSA, VDE, IEC, CE) for your region and application.

- Special Features: Hospital-grade (green dot), outdoor-rated, surge-protected, shielded for EMI/RFI, locking connectors, or angled plugs for tight spaces.

Not sure which cord meets your needs? Get personalized guidance with our Power Cord Selector Tool or contact our technical team.

Benefits of Using the Right AC Power Cord

Investing in the correct, high-quality AC power cord provides significant advantages for both safety and performance:

- Electrical Safety: Reduces the risk of shocks, short circuits, and fire hazards.

- Device Performance: Ensures stable, uninterrupted power for sensitive electronics and high-demand equipment.

- Longevity and Durability: Premium materials and robust construction increase cord lifespan, especially in demanding environments.

- Regulatory Compliance: Certified cords meet legal and insurance requirements, streamlining inspections and audits.

- Operational Versatility: Wide variety of cord lengths, connector types, and grades to match any application.

- Reduced Downtime: Fewer equipment failures and reduced maintenance costs from using reliable, properly rated cords.

Wondering about the value of hospital-grade, outdoor, or locking AC power cords? Explore our in-depth resources on hospital-grade and outdoor-rated power cords.

Safety Considerations and Best Practices

Proper handling and maintenance of AC power cords are vital to avoid electrical hazards and extend cord life. Follow these best practices:

- Grounding and Polarization: Use grounded (three-prong) or polarized cords for appliances with metal enclosures, power tools, and equipment requiring earth ground. Polarized plugs ensure correct wiring orientation for added safety.

- Inspection: Regularly check cords for cuts, frays, exposed copper, melting, or loose connectors. Replace damaged cords immediately to eliminate shock and fire risks.

- Proper Routing: Avoid running cords under carpets, through doorways, or across walkways. Use cable management systems to prevent tripping and pinching.

- Environmental Protection: Select cords rated for moisture, sun exposure, temperature extremes, and chemicals when used outdoors or in industrial settings.

- Certification Labels: Only use cords with visible, recognized certification marks such as UL, CSA, CE, VDE, or IEC, indicating compliance with quality and safety standards.

- Load Management: Don’t overload power strips or outlets. Use surge protectors where appropriate, and never daisy-chain multiple extension cords.

Have questions about electrical codes or safe installation? Visit our power cord safety standards resource center for expert guidance.

Frequently Asked Questions about AC Power Cords

- What is the difference between AC and DC power cords?

- AC power cords carry alternating current, which reverses direction periodically. DC power cords are designed for direct current, flowing in one direction only, and are typically used for devices requiring stable, constant voltage such as laptops and battery chargers. Learn more about DC power cord differences.

- Can I use an international AC power cord in North America?

- Generally, no. International cords may have incompatible plug shapes, voltage ratings, and frequency standards. Using the wrong cord may cause equipment damage or pose safety risks. Always match the plug and voltage to your country’s standards, or use certified adapters and voltage converters.

- What does “hospital-grade” mean for AC power cords?

- Hospital-grade cords exceed standard requirements for grounding, insulation, and strain relief. These cords are suitable for medical environments and are marked with a green dot for easy identification. They are critical for life-support and patient-connected equipment. Explore hospital-grade cord options and regulations.

- How do I determine the correct wire gauge for my AC power cord?

- Wire gauge depends on the cord’s length and the current draw of your equipment. Thicker wires (lower AWG numbers) are required for longer runs or higher currents. Consult manufacturer charts or an electrician for guidance.

- What certifications should I look for in an AC power cord?

- Look for certification marks such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), VDE (Verband der Elektrotechnik), CE, or IEC. These ensure the cord meets recognized safety and performance standards.

- Can I use an extension cord instead of a dedicated AC power cord?

- Extension cords are suitable for temporary use and light loads, but should not replace a properly rated, device-specific AC power cord for permanent installations or high-power equipment. Overuse of extension cords increases the risk of overheating and fire.

- What is the difference between a cord set and a power cord?

- A cord set typically includes both the AC power cord and molded connectors at each end (plug and receptacle). A power cord may refer to just the cable without connectors, though terms are sometimes used interchangeably in the industry.

How to Buy AC Power Cords: Decision Factors and Purchasing Guide

Ready to purchase an AC power cord? Follow these steps to ensure you choose the right product for your electrical and operational needs:

- Identify device requirements: Gather details on input voltage, current draw, plug type, connector style, and environmental considerations.

- Check regional standards: Verify plug and voltage compatibility for your location or export market.

- Determine cord length and wire gauge: Select an appropriate length for your installation, and use the recommended wire gauge for your current and distance needs.

- Prioritize safety certifications: Ensure cords are certified by recognized agencies for your country and application.

- Consider special features: Look for locking connectors, angled plugs, hospital or outdoor grades, surge protection, or custom assemblies as required.

- Evaluate supplier reputation: Purchase from reliable, experienced manufacturers or distributors who stand behind their products and provide technical support.

- Assess value-added services: Some suppliers offer cable labeling, bulk packaging, or kitting for streamlined installations or inventory management.

Looking for bulk or custom orders? Browse our AC power cord catalog or request a quote for personalized solutions.

AC Power Cord Maintenance and Troubleshooting

Routine care and timely replacement of AC power cords are key to maintaining electrical safety and system uptime. Here’s how to optimize cord lifespan:

- Storage: Coil cords loosely and store in a dry, cool location away from sunlight, moisture, and chemicals.

- Cleaning: Wipe with a damp, non-abrasive cloth. Avoid harsh solvents that can degrade insulation and jackets.

- Replacement: Replace cords at the first sign of damage, overheating, or connectivity issues.

- Asset Tracking: Label cords and monitor usage in high-traffic or mission-critical areas to schedule proactive replacement.

- Testing: Periodically test cords with a continuity tester or insulation resistance meter, especially in industrial or medical environments.

Having trouble with power cords? Use our troubleshooting guide for step-by-step diagnostics and solutions.

Advanced AC Power Cord Features and Innovations

The field of AC power cords continues to evolve, with manufacturers introducing features to meet specialized needs in safety, performance, and convenience. Popular innovations include:

- Right-angle and low-profile plugs: Ideal for tight spaces behind furniture, racks, or appliances.

- Locking connectors: Prevent accidental disconnects in industrial, medical, and data center environments.

- Retractable and coiled cords: Enhance portability and cable management for mobile equipment.

- Color-coded cords: Simplify identification and reduce errors in complex installations.

- EMI/RFI shielding: Protect sensitive electronics from electromagnetic and radio-frequency interference.

- Smart cords with integrated monitoring: Track power consumption, temperature, and cord status in real-time for predictive maintenance.

Want to learn more about the latest advancements in power cord technology? Explore our >manufacturer directory and custom solutions for cutting-edge options.

Conclusion: Why Choosing the Right AC Power Cord Matters

AC power cords are a critical component of every electrical system, impacting everything from user safety to device reliability and regulatory compliance. By understanding cord construction, standards, applications, and best practices, you can make confident purchasing decisions and ensure your equipment operates safely and efficiently. For more information, technical guidance, or to explore a comprehensive selection of certified AC power cords and assemblies, contact our experts today.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services